We were asked to join the team as a result of our pedigree in rapid tooling and our knowledge and experience in medical tooling and moulding. We worked closely with the team with the aim of delivering 5,000 units of the newly designed ventilator in extremely tight timescales.

We started work in the early hours of Friday 3 April 2020 and the first parts of the tools were produced within a non-stop 36 hours. Working 24/7 within 8 days we had moved through design for manufacture, purchasing, tooling manufacture for all 11 tools, capability studies, material selection and had started to mould production components.

From one the engineers at RedBull Racing here is the final built BlueSky machine:

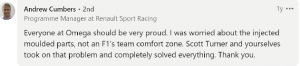

This was the response from Andrew Cumbers, Programme Manager at Renault Sport Racing:

The work that we did on the Project BlueSky ventilator made an appearance on the OneShow on BBC1 on Tuesday 28th April.