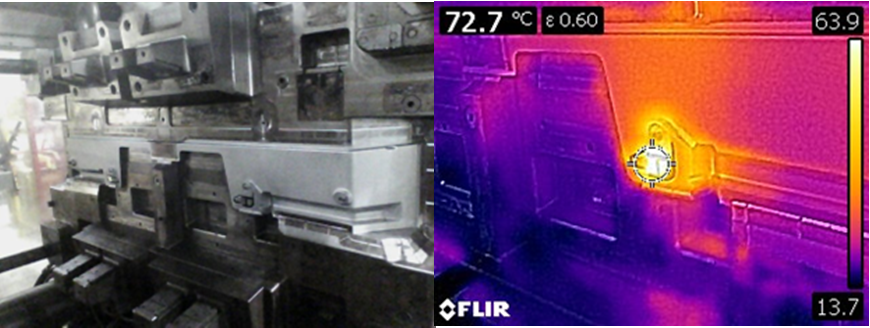

Thermal imaging process shown on one of our tools.

Reshoring is experiencing a huge surge, from overseas back to the UK. There are many benefits to your business by reshoring your plastic injection moulding and tooling needs.

Benefits include:

- Removing the rising international freight costs,

- Reducing your environmental impact,

- Faster turnaround and shorter lead times,

- Confidence of supply due to short journey to site to view tooling or components.

- Tool material certification and assurance.

Struggling with inefficient tools? We have recently introduced a thermal imaging process which allows us to accurately pinpoint hot spots in your tool. This important technology allows our specialist team to make recommendations on how to improve the tools’ efficiency. The thermal imaging gives the team a new capability to ensure that component parts are being released from the press at the right temperate, optimising the process and minimising cycle times, significantly reducing the risk of non-conforming parts.

The technology has been used to discover reasons that components haven’t met quality standards, allowing our customers to fix these issues before continuing with production.