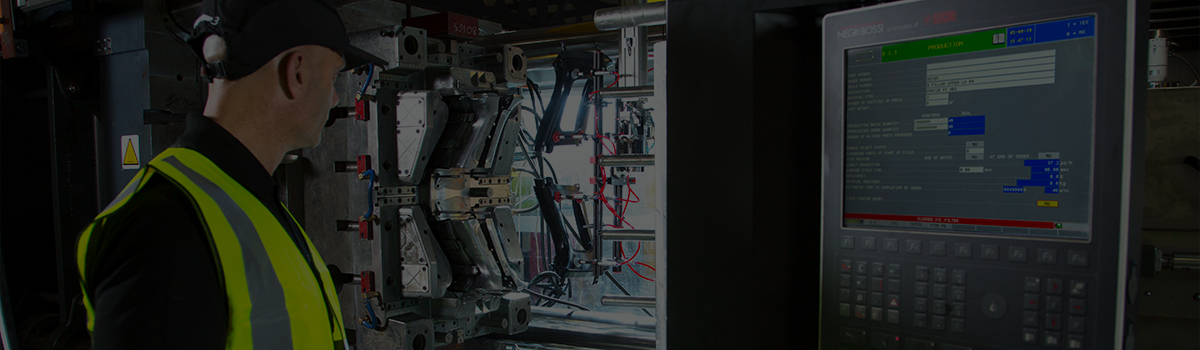

Our moulding capabilities range from 40-1,300 tonnes with 30 machines encompassing both hydraulic and all-electric injection moulding machines within our group facilities at Omega Plastics and Signal Plastics.

Our years of experience have seen us deliver a vast range of products in varying volumes from automotive to healthcare devices. We are able to offer our customers both low and high volume plastic injection moulding as part of our turn-key solution service.

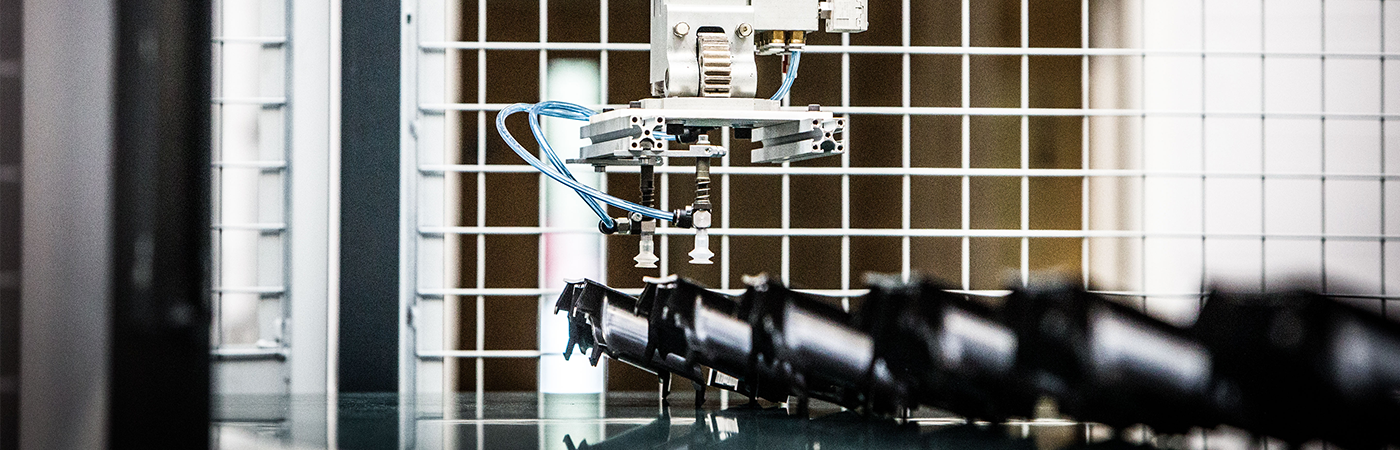

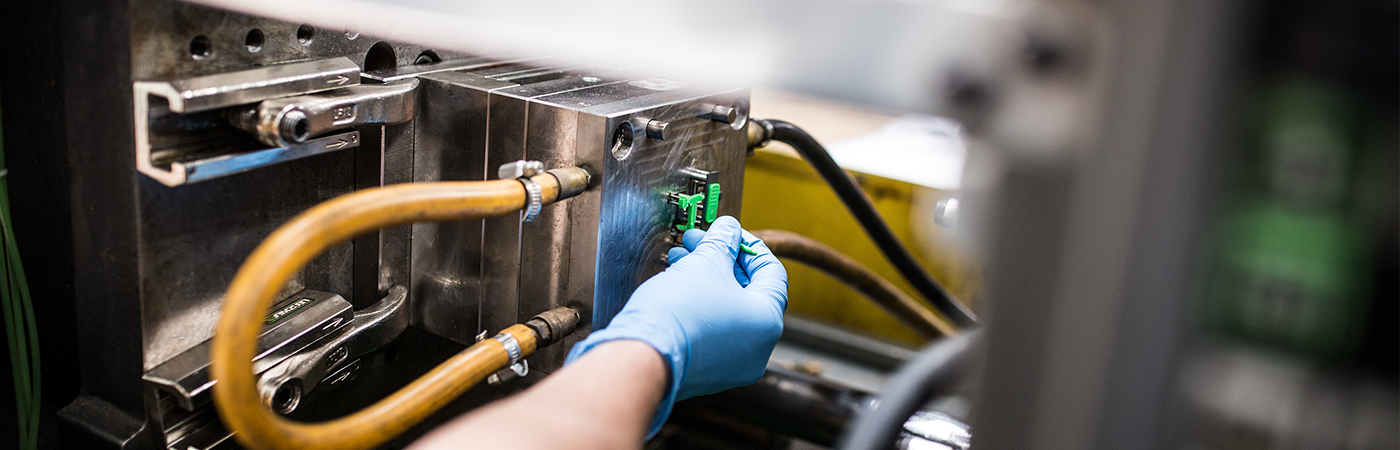

Our highly skilled team are fully trained in both hand-loaded development plastic injection mould tooling and fully automated tooling.

With such a large customer base, we work with an extensive range of engineering polymers and in any volume you require. In addition, we can over-mould off the shelf and bespoke inserts, metal fret connectors or other plastic injection moulded parts to give your product a professional finish.

Sub-assemblies can also be produced as part of our added value services and packaged to your requirements. The same applies for various subcontracted finishing processes, including:

- Painting

- Digital imaging

- Pad printing

- RF shielding

- Packaging and stillages

- Injection moulding quality control

To enquire about our plastic injection moulding capabilities and what we can offer you, please get in touch with us today!