Whether its single cavity or multicavity, our tools to support with production tooling are all made from high-quality materials to offer precision and longevity for your products.

At Omega Plastics Group, we offer several types of tooling and manufacturing processes as part of our plastic injection tooling service.

Expert Production Tooling Services

Our production tooling service, sometimes referred to as hard tooling, incorporates both cold and hot feed systems that are built into industry standard die sets to provide customers with first class tools for their projects. As part of our production tooling offering, we trial and validate the mould in-house at our facilities prior to production at Omega or the delivery of mould tools for customers who would mould themselves.

Production tooling in manufacturing, or machine tooling, involves the process of material design, cutting, forming and shaping materials to produce prototype components. It is a critical aspect of plastic injection tooling or plastic injection moulding manufacturing processes.

The cost of tooling, particularly production tooling, depends entirely on the complexity and size of the project. Since our production tooling process is completely bespoke to each project, the cost of tooling and of our plastic services can differ between clients. Our team of tooling in manufacturing specialists, who have experience in several types of tooling from rapid tooling, known as soft tooling, bridge tooling or prototype tooling, to hard tooling, can support you with a bespoke price for your project.

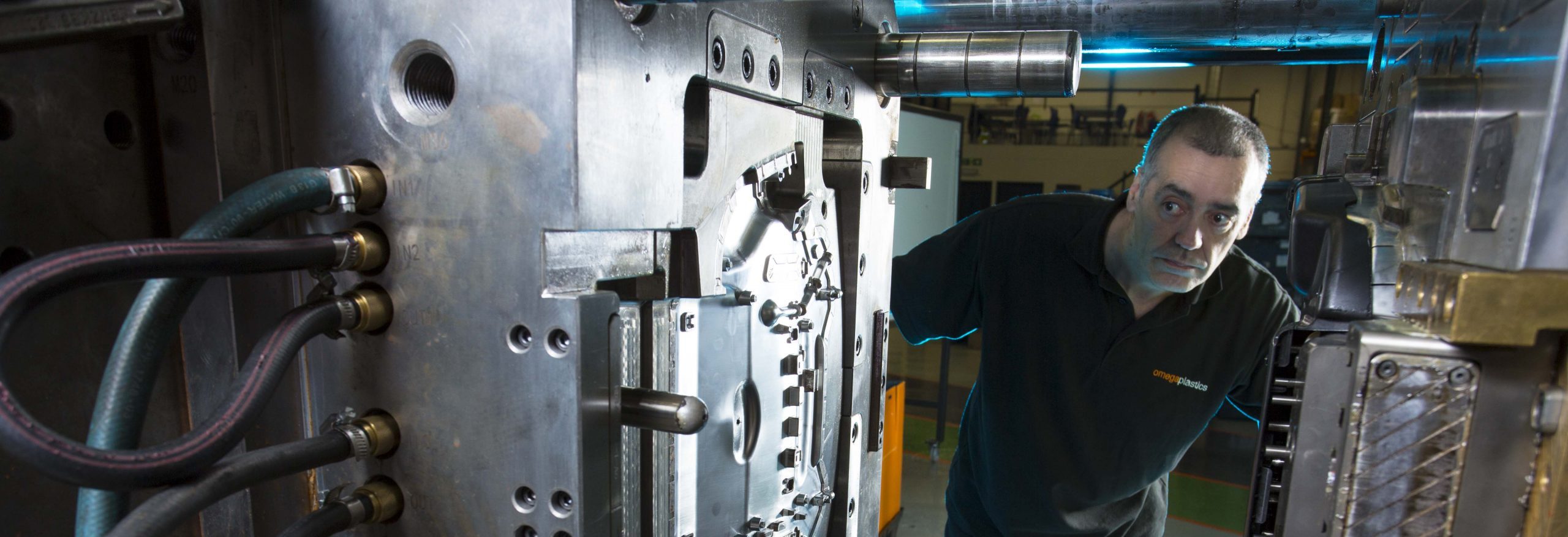

Our Production Tooling Facilities

Our production tooling is fully designed and manufactured in-house at our Gateshead-based facility, Omega Plastics. Here, we have the capabilities to meet a range of manufacturing processes, including Design For Manufacture (DFM), Electrical Discharge Machining (EDM), machining, polishing and fitting.

Our production tooling capabilities acknowledge the diverse range of sectors we cater for, which include automotive, medical, consumer products, industrial and technical products and aerospace and defence. At Omega Plastics Group, we understand that volume requirements can differ depending on your project requirements. We can develop production tooling in:

- P20, a pre-toughened tool steel which provides good longevity on most standard polymers.

- H13 or Stavax tool steel,fully hardened steels which can enhance production tooling volumes and is commonly used for medical

At Omega Plastics Group, we are committed to providing our customers with high-quality production tooling to support their project. Whether our team are moulding products for clients or sending mould tools to customers who conduct their own manufacturing production process, our production tooling service is bespoke and designed to be flexible around your needs.

To learn more about our plastic services and how we can meet your plastic injection tooling or plastic injection moulding needs through production tooling, get in touch.