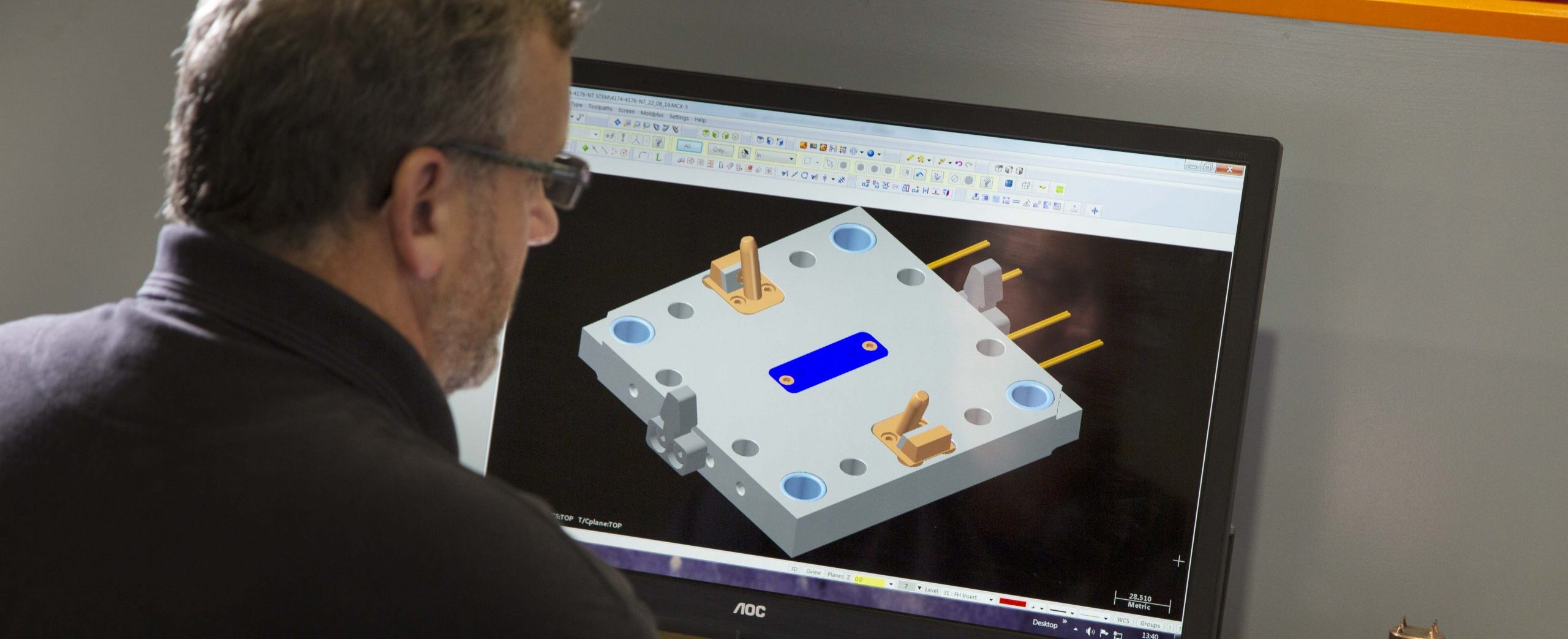

Our engineers are experts in product development and additive manufacturing, and will provide you with specialist Design For Manufacture (DFM) services to ensure your products are optimised for the next step in the manufacturing process.

Omega Plastic Group’s Design For Manufacture (DFM) service is one of several manufacturing processes offered as part of our plastic injection tooling service and works to ensure your products are ready to go through an important design for manufacturing process: the plastic injection moulding stage, regardless of whether your project requires low volume or high volume moulding.

Expert Design For Manufacture (DFM) services

As part of the pre-manufacture analysis and material selection manufacturing process of Design For Manufacture, our team can help reduce the risk associated with new product introduction to your application. By meeting design for manufacturability standards. following this manufacturing process can help avoid costly change activity during mass production moulding.

Additionally, Omega Plastics Group can provide complimentary rapid prototyping services including stereo lithography prototyping (SLA), selective laser sintering (SLS), vacuum casting rapid prototyping and 3D printing as part of our plastic services.

At Omega Plastics Group, our Design For Manufacture (DFM) is a completely bespoke service which can be tailored to meet the requirements of different client projects. Each rapid prototyping manufacturing process can offer a variety of post-mould finishes and, when coupled with our range of painting techniques, your plastic injection tooling project will achieve a professional look. At this stage, our engineers, who are experts in the product design, product development and design for assembly aspects of Design For Manufacture (DFM), can recommend further plastic injection moulding options to achieve a more aesthetically pleasing and functional product.

Our Design For Manufacture (DFM) facilities

At Omega Plastics Group, all of our Design For Manufacture projects are offered from our Gateshead-based facility, Omega Plastics.

Our facilities are designed to cater for the various sectors we operate in, including automotive, medical, consumer products, industrial and technical products and aerospace and defence.

As well as our plastic injection tooling services, we also offer plastic injection moulding in low volume and high volume requirements, and added value services to provide you with a full turnkey service, which includes assembly, supply chain management and metrology and validation. Due to our bespoke approach to projects and the additional plastic services we offer, manufacturing costs for the design process differ based on the service you require.

To learn more about our Design For Manufacture (DFM) service and the other design for manufacturing offerings we can supply, including manufacturing costs, design for assembly and product development, get in touch with our team.