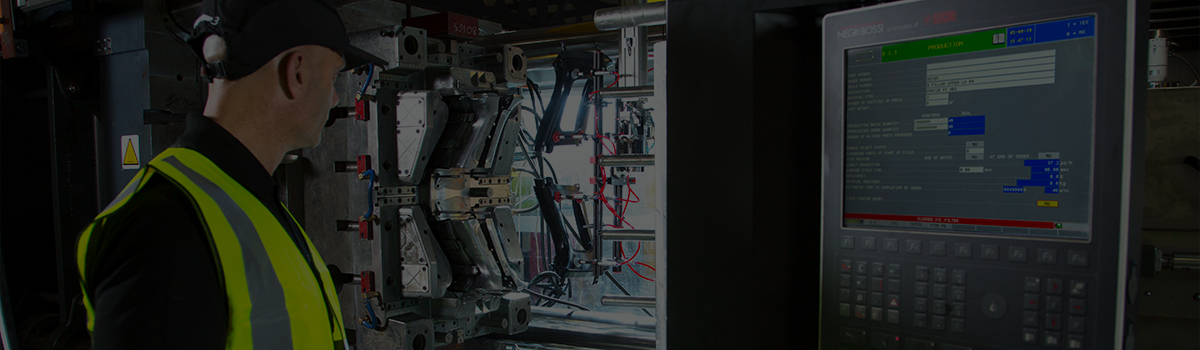

Our plastic injection moulding capabilities range from 40-1,300 tonnes with 30 machines encompassing both hydraulic and all-electric injection moulding machines to support our clients with their injection moulding needs.

At Omega Plastics, we have years of experience in delivering a vast range of products engineered through the plastic injection moulding process.

Our expert plastic injection moulding services

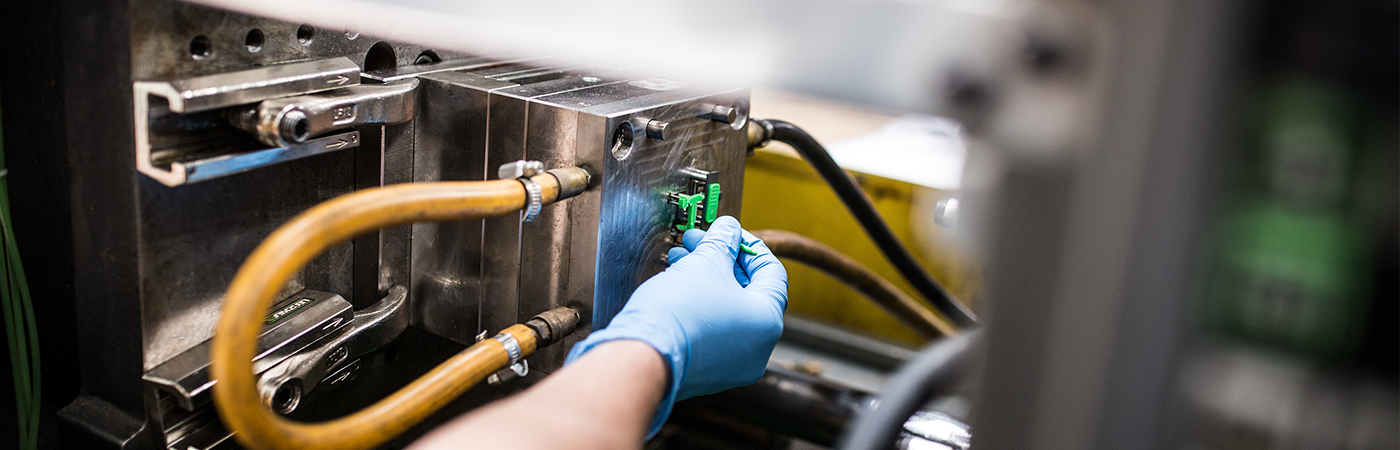

Plastic injection moulding is a mass-production process used to create plastic parts for a variety of sectors by melting plastic pellets and injecting the liquid material into a custom-shaped mould. At Omega Plastics, our highly skilled team are fully trained in both hand-loaded development plastic injection moulding and fully automated tooling, meaning we can support you throughout the injection moulding process with ease.

All designed and manufactured to meet specific client requirements, our plastic injection services, like our plastic injection moulding services, allow us to offer our customers both low volume plastic injection moulding and high volume plastic injection moulding as part of our turnkey service.

With such a large customer base and our clients working across several sectors, including automotive, medical, consumer products, industrial and technical products, and aerospace and defence, we work with an extensive range of polymers in any volume you require. Our plastic injection services are completely bespoke, meaning we can over-mould off-the-shelf and custom inserts, metal fret connectors or other plastic injection moulded parts to give your product a professional finish.

At Omega Plastics, we offer a range of additional plastic injection services to enhance your plastic injection moulding projects. Supported by our expert plastic injection moulders, we can provide design for manufacture assistance or product assembly and packaging services, which can be produced as part of our added value services and packaged to meet your requirements.

The same applies for various subcontracted finishing processes, including:

- Painting

- Digital imaging

- Pad printing

- RF shielding

- Packaging and stillages

- Injection moulding quality control

Our plastic injection moulding facilities

As part of our plastic injection moulding services, we design and manufacture a range of injection mould products at our Gateshead facility, Omega Plastics. Here, our plastic injection moulders have the capability to meet our customers’ bespoke insert moulding requirements, as well as offering other plastic services, like plastic injection tooling, design for manufacture and injection moulding project management.

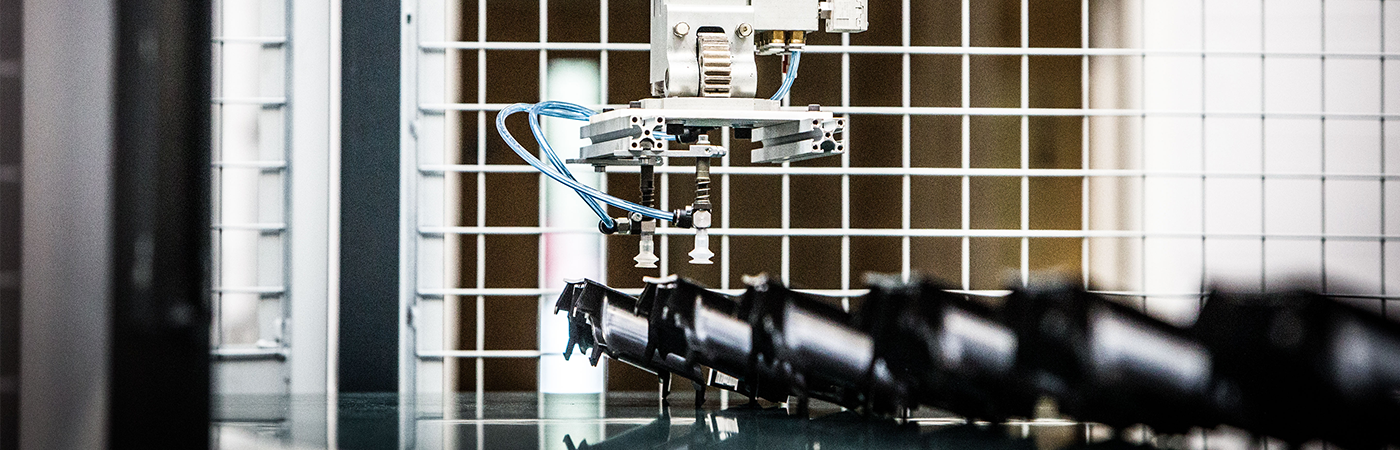

Our plastic injection moulding services, especially our high volume plastic moulding, is offered at Signal Plastics, our second facility based in Washington which houses overhead robotic equipment and 15 injection moulding presses. Our expert plastic injection moulders at Signal Plastics can manufacture larger parts in higher volumes for sectors including automotive, medical and more.

To enquire about our plastic injection moulding services, our facilities and what we can offer your bespoke plastic injection mould project, get in touch with our team at Omega Plastics Group today.